|  |

| Tim Cook 1979 | Apple CEO Tim Cook 2012 |

Made in the U.S.A.

Abstract:

In a recent interview with the Apple CEO Tim Cook, thanks to The Register for the pictures, there was a short discussion on asembling computer systems in the United States. There have also been short articles on which systems are being manufactured closer to the nation of purchase. Debunking of false 1st world manufacturing drivers as well as industry stated drivers for 1st world manufacturing will be reviewed. The United States is not the only nation which will benefit from distributing manufacturing capabilities outside of large 3rd world manufacturing facilities, so they are also worth the discussion.

|

| North America, courtesy: The Lonely Planet |

When the United States was a mere "colony", most of the manufacturing was done in England. Much of this started to change during the Industrialization of America. The most significant sweeps in manufacturing, perhaps occurred during World War 1 and World War 2, when so much of the manufacturing capacities around the world were destroyed.

Honestly, I don't remember anything being manufactured in the United States in recent time, except building materials. Of course, wood based product are increasingly being produced in South America, and dry wall is being increasingly produced in China. A recent trip to Home Depo had made me realize this - and helped me to understand that the next building-boom will not necessarily drive U.S. industry.

|

| Apple 2012 21" iMac, courtesy The Register |

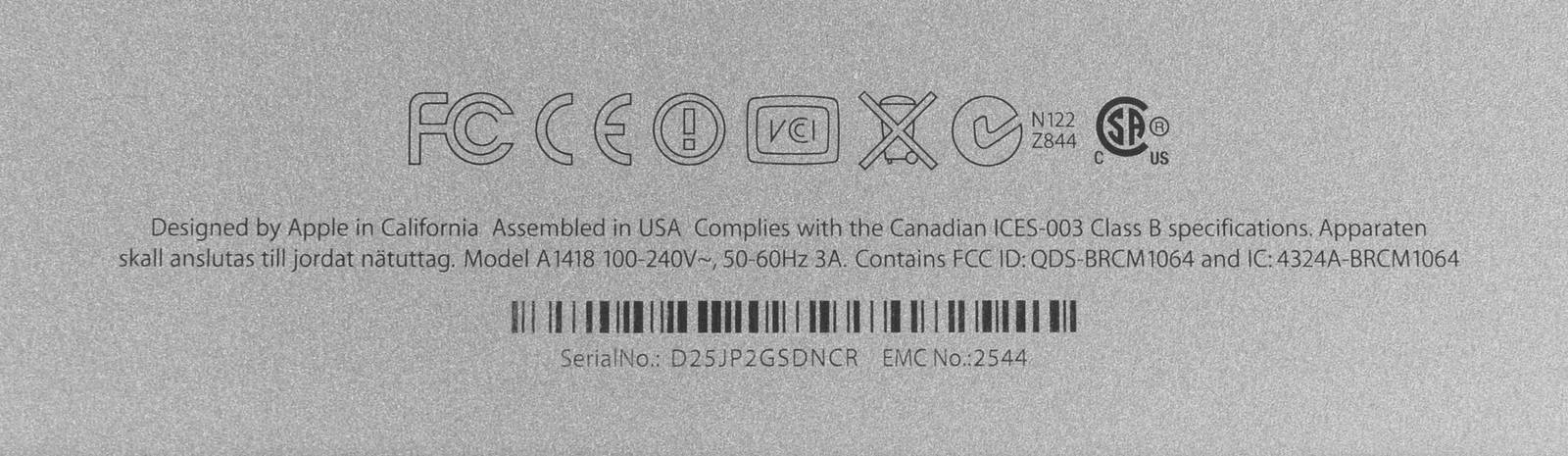

During the "tead down" of a 2012 21" iMac, it was noted that the consumer product was assembled in the United States. People have mentions that 2011 Apple iMac's have been assembled in the U.S.A., as well as Mac Pro in 2007, a Mac Mini in 2006, as well as a decade-old Apple Macintosh G3. Computer World mentioned the 1999 Power Mac, the first iMac in 1988, and even the two decade old Apple II.

One of the most interesting quotes from Apple CEO was in regard to manufacting of Apple consumer electronics:

"It's not as much about price," he said, "it's about the skills, etcetera. Over time there are skills that are associated with manufacturing that have left the US."Remembering former CEO of Apple, Steve Jobs, when he was "fired" from Apple, he started a new computer company called "Next", in the 1980's. During that time, they assembled computer systems in an office - but they could never keep up with the demand. Next turned into a "software company" and was later re-purchased by Apple. Computer World may have presented the argument for consumer electronics best:

And in Apple's market, according to Cook, those skills weren't here to begin with. "The consumer electronics world was really never here," he said, "and so it's not a matter of bringing it back, it's a matter of starting it here."

Cook's announcement was both a recognition of real-world manufacturing and a bit of a departure from former CEO Steve Jobs' opinion. In a meeting with President Obama in 2011 just months before his death, Jobs reportedly said, "Those jobs aren't coming back," when the President asked what it would take to make iPhones in the U.S.How will Apple bring more manufacturing to the United States? Well, apparently Apple does not have the know-how to do it themselves, at an economically feasible cost.

Cook said that Apple will invest more than $100 million in the project -- pocket change for a company that has over $120 billion in the bank -- but that it wouldn't do it themselves. "We'll be working with people, and we'll be investing our money," he said.In essence, Tim Cook was right - manufacturing in the United States was, and still is, a difficult endeavour. Regulations are a huge issue, perhaps even a liability issue, that Apple does not feel comfortable dealing with on a larger scale.

|

| Apple 2011 iMac, courtesy arstechnica |

More than Apple?

It seems more computer manufacturering is happening outside of China. A recent article from the New York Times mentions:

Five years ago, he says, H.P. supplied most of Europe’s desktops from China, but today it manufactures in the Czech Republic, Turkey and Russia instead. H.P. sells those kinds of computers particularly to business customers.While not the cost structure of "first world" manufacturing, it is still interesting.

|

| Dumb Reporter for New York Times, courtesy calvinayre |

What exactly drives manufacturing, some may ask?

The notorious New York Times suggests:

Today, rising energy prices and a global market for computers are changing the way companies make their machines.Immediately after making this statement, they went on to use computer consumption in Europe as s supporting argument, which immediately destroys half of the original statement, since Europe is a First World nation and had always consumed computers, thus this "global market" had not changed, from a consumption perspective. This only leaves Energy.

Also in the same article, The Times mentions:

In 1998, President Bill Clinton visited a Gateway Computer factory outside Dublin to cheer the role of American manufacturers in the rise of a “Celtic Tiger” in technology. That plant was shut in 2001, when Gateway elected to save costs by manufacturing in China.Energy was at its lowest point during the Clinton years, and started to rise during the G.W. Bush years, so cheap to rising cost of energy was part of the equation to outsource to China. Energy costs are higher in the 1st world than in the 3rd world, where reduced regulation means more plentiful energy at a lower cost.

If The New York Times can't present a cohesive argument, then what are the incentives?

The Main Drivers for 1st World Manufacturing:

The previous New York Times article mentioned some cohesive points on locality of components. Manufacturers who have major components produced in the 1st world may find advantageous assembly in the 1st world. For apple, the following proves interesting:

Intel, which makes most of the processors, has plants in Oregon, Arizona, New Mexico, Israel, Ireland and China. ... The special glass used for the touch screens of Apple’s iPhone and iPad, however, is an exception. It comes primarily from the United States.However, for cheaper [Android] phones, hand-held games, and laptops, the opposite seems to be the case, manufacturing may never come to the 1st world again:

Many other chip companies design their own products and have them made in giant factories, largely in Taiwan and China. Computer screens are made in Taiwan and South Korea, for the most part.

Time to Market is a huge benefit for one Chinese manufacturers. ComputerWorld also mentioned China's Lenovo manufacturing of laptops in North Carolina in October 2012:

The company, which is based in China, earlier this month announced it would open a factory to make computers in Whitsett, N.C. -- its first such facility in the U.S.

...

Manufacturing in the U.S. will help Lenovo get its products to customers more quickly, said Peter Hortensius, senior vice president of the product group at Lenovo...The company will manufacture ThinkPad laptops and tablets starting early next year, and with the new factory, Lenovo hopes computers could reach customers within a week, or in some cases, overnight. But initial supplies of products like the ThinkPad Tablet 2, which will become available in October, will not be made in the U.S. factory.

...

Many Lenovo computer shipments originate from China and are supposed to reach customers in 10 days, but in some cases take weeks. The company also has factories in Japan, Brazil, Germany and Mexico.

The same article in ComputerWorld also dicusses Lenovo's desire to appear to patriotism for market penetration:

The "Made in USA" tag on computers manufactured in North Carolina will resonate with some buyersIn some cases, it may be tax incentives, but The New York Times suggested that is not enough, by placing the failure in the same sentence as the reason.

A Dell factory in Winston-Salem, N.C., for which Dell received $280 million in incentives from the government, was shut in 2010 (Dell had to repay some of the incentives).

There are clearly drivers for 1st world manufacturing.

|

| President Obama, courtesy Carnagie Mellon School of Computer Science |

This is always the question. Perhaps, this is best mentioned at the end of the New York Times article...

As cheap as a Chinese assembly worker may be, an emerging trend in manufacturing, specialized robots, promises to be even cheaper. The most valuable part of the computer, a motherboard loaded with microprocessors and memory, is already largely made with robots.The ultimate answer is, there are not many good high-wage jobs in manufacturing any longer. This was painfully made clear during President Obama's campaign tour across the country - everywhere he went, he talked about manufacturing.

|

| U.S. Manufacturing Jobs during Obama Presidency, courtesy The American Thinker |

Computer manufacturing will not bring it back.

No comments:

Post a Comment